(269) 496-8495 inquiry@thplastics.com

Products and Capabilities

Safety

Quality

Productivity

Continual Improvement

Capabilities

TH Plastics is committed to improving the environment both inside and outside our facility. Recycling programs have been in place and environmentally friendly suggestions are incorporated regularly.

Working with customers to eliminate waste is a high priority and we have had great success in transportation, packaging and resin selection.

In some cases using recycled material can provide a green solution for the customer to help keep their products more environmentally friendly as well as save them money!

TH Plastics has four manufacturing facilities in Mendon Michigan, Bowling Green, Findlay and Tiffin Ohio with a variety of part design, injection molding and finishing capabilities.

- Complete Design capabilities

- In-Mold Labeling experts (IML)

- Dedicated Program and Project Management

- Horizontal and Vertical Injection Molding Machines (50 – 1100 TON)

- Insert Molding

- Scientific Molding (utilizing cavity pressure for process control)

- Mold Making

- Laser Etching and Part Marking

- Sonic, Heat Stake, Rotational, and Linear

- Vibratory Welding

- Assembly (simple to complex)

- Custom Labeling and Packaging

- Pad Printing

- Hot Stamping

- Experience with running multiple colors in multiple part configurations.

Products

TH Plastics supplies products to a variety of markets. Appliance, Automotive, Industrial and Consumer Products comprise 95% of our diversified business. Each industry has a unique set of procedures and requirements for product development and we have been able to incorporate each one to continuously service our wide customer base.

TH Plastics has the ability to meet the world class manufacturing requirements of virtually any industry. We are 100% committed to serving our customers in these industries through our continued investment in cutting edge technology and in the expansion of our capabilities.

Technology

TH Plastics continuously invests in the latest technology to ensure product quality while remaining competitive in a global market. Six axis robots for product removal and automated assembly equipment provide for consistent processes without incurring significant costs.

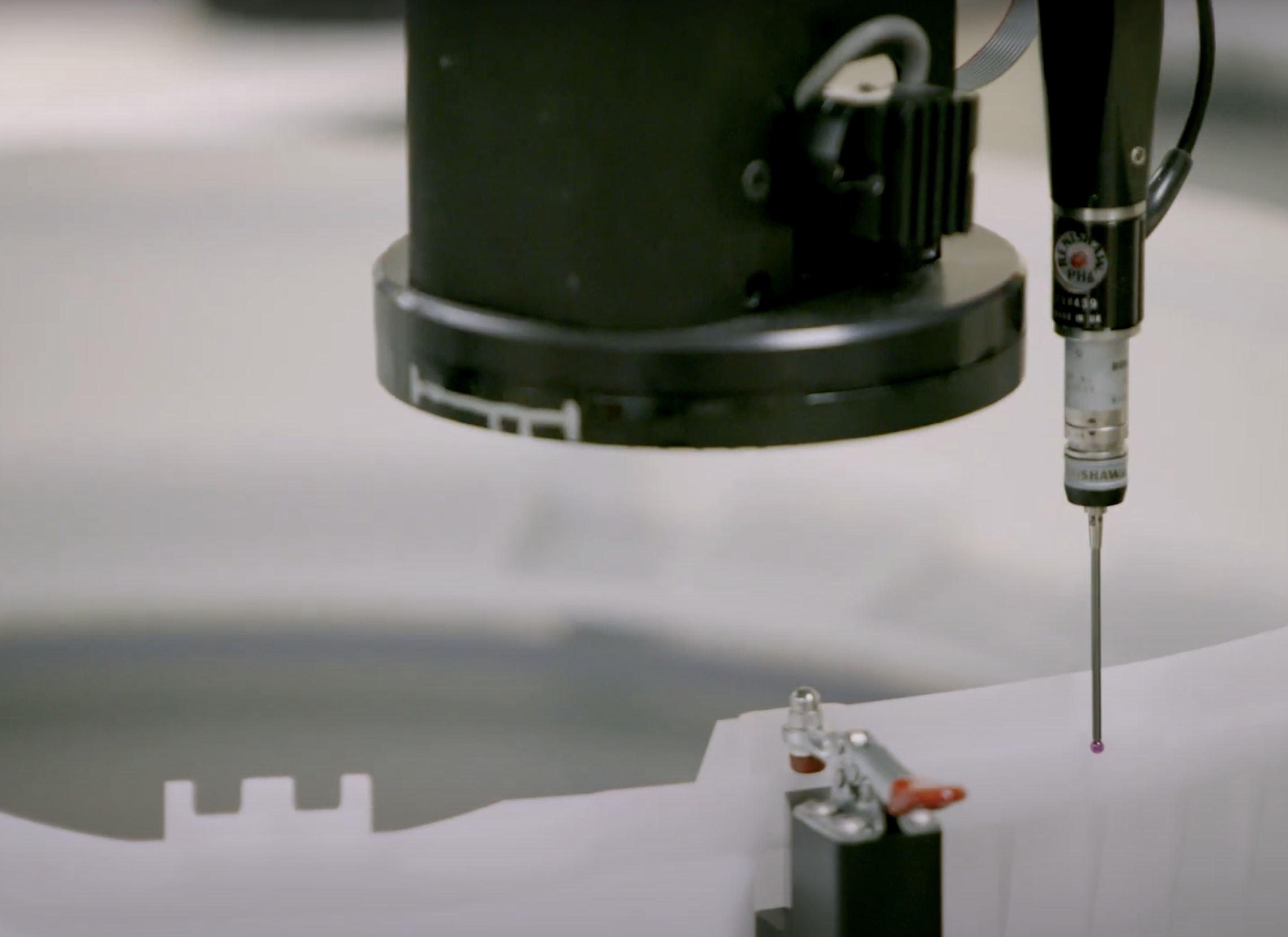

Scientific molding has been adopted as a standard for today’s highly technical products and engineering grade resins. Detecting cavity pressure is the most effective method of monitoring the process and allows data-driven decisions to be made on a daily basis.

Our Enterprise software was developed for Injection Molding facilities and provides complete system integration. Customer Service and Delivery performance enhances our flexibility to meet any fluctuations in customer orders.

Engineering

The Engineering Department at TH Plastics brings a wide range of experience to our mission. First and foremost, our Program Managers have a strong knowledge of Plastic Processes, which provides our customers with manufacturing ready designs. Designing for Manufacturing ultimately reduces cost through tooling, processing and longevity of capital equipment (tooling) while ensuring the most optimal recipe for superior Quality.

The CAD/CAM equipment hosts a variety of software packages to allow file transfer and conversion with almost any customer-specific file. Reviewing CAD files, manipulation for potential improvements, and tool design are all done onsite within the Engineering Department. Part layout, comparative analysis and Product Approval Process are catered to each customer’s specific requirements.

The Engineers at TH Plastics function as an extension of your company’s Engineering Department by integrating with your project managers. They are readily available to support our customer’s requirements and exceed their expectations.

Quality

TH Plastics continuously invests in the latest technology to ensure product quality while remaining competitive in a global market. Six axis robots for product removal and automated assembly equipment provide for consistent processes without incurring significant costs.

Scientific molding has been adopted as a standard for today’s highly technical products and engineering grade resins. Detecting cavity pressure is the most effective method of monitoring the process and allows data-driven decisions to be made on a daily basis.

Our Enterprise software was developed for Injection Molding facilities and provides complete system integration. Customer Service and Delivery performance enhances our flexibility to meet any fluctuations in customer orders.

Contact Sales

Brad Underwood

Call

(269) 496-8495 x1129

Jason Jones

Call

(269) 496-8495 x1178